Having Trouble Writing your CDR Report ?

Get in Touch with Our Writers to get the Help you Need and

Avoid Possible Rejection!

or talk to our writers at +61 481 614 316 / +61 483 968 416

Get Free Consultation

Career Episode Report Example for Professional Engineer

A competency demonstration report (CDR) requires migrant engineers applying to Engineers Australia to write three career episode reports (CERs). Career Episode Report for Engineers Australia gives detailed information on technical and other skills an engineer applied to the project described. You must demonstrate your professional competencies in your career episodes. Here is a writing style for a Career Episode Report Example for Professional Engineer.

PART-I INTRODUCTION

CE 1.1

The following career episode is on the basis of the project titled “BUCHI Unit for Protein Analysis”. This project was carried out by me when I was working as an Executive Trainee in the Manufacturing Department. The name of the company that I worked during this time is the XXX (name and location of company). The duration of time for the successful completion of the project was from September of the year 2014 to December of the same year.

PART-II BACKGROUND

CE 1.2

XXX (Company Name) is a part of XXX (Company Name) based in XXX (Company’s Location). Both businesses run independently with different headquarters, XXX (Company Name) is headquartered in DLF XXX (location) and Pharmaceuticals in XXX (Location). XXX site became the mother factory in India that manufactures Horlicks and its variants in the Indian market. The capacity of the plant is approximately 100,000 metric tons per annum. Currently, XXX (Company Name) has 3 different sites that manufacture the same product, but XXX (Company Name) outstands incapacity. Protein calculation is an important activity in the food and chemical industries. However, the process includes handling of chemicals such as sulfuric acid and organic liquids and the existing equipment used in the process had hot surfaces, and it was not shockproof. Hence, it is deemed essential to enhance the safety of the analyst and also to increase the efficiency of the protein calculation system in terms of energy saving which is carried out in this project.

CE 1.3

The main aim of this project is to increase the efficiency of the BUCHI Unit for Protein Analysis.

The specific objectives of the project are provided as follows:

- To analyze the current systems risks and issues

- To enhance the safety of the analyst during the protein calculation process

- To design a new system that matches the requirements and minimize the potential risks

- To install the new system

- To commission under the supervision of the safety manager

- To review the new system by doing trials

- To increase the efficiency of the protein calculation system in terms of energy saving

- To prepare a data analysis report on energy consumption

CE 1.4

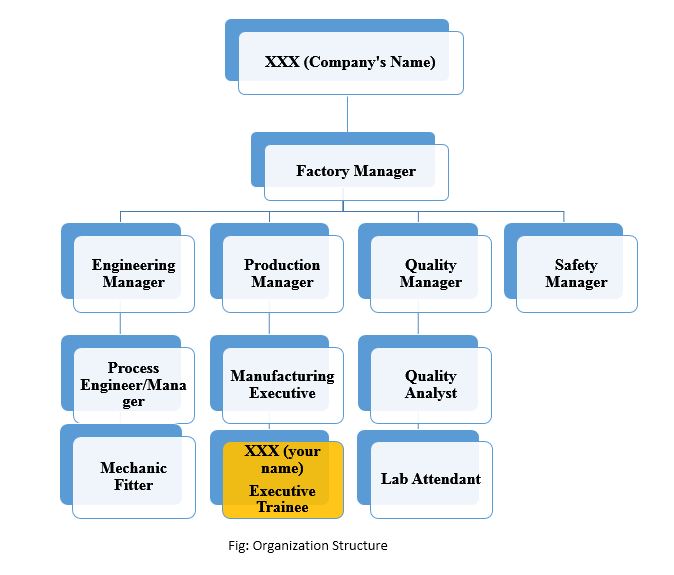

I did this project on the organization XXX (Company’s Name and Location) under the supervision of Mr. X. The organizational structure for this project is shown as below:

CE 1.5

The roles and responsibilities that I followed during the completion of this project are presented as follows:

- Selection of the type of glass to be used which is resistant to acids, alkalis and organic substances.

- To ensure leak tightness to prevent leaks of harmful acid fumes.

- To decide the size of the condensation zone to prevent splashing of acids.

- To coordinate with process engineer to ensure a perfect installation.

- Review of the design of the new equipment and its suitability with the product to be analyzed for protein calculation.

- To review the data in terms of the total time taken by existing and new system.

- To check the efficiency of the system in terms of energy consumption.

PART-III PERSONAL ENGINEERING ACTIVITY

CE 1.6

The theoretical knowledge that I had gained during my undergraduate program was translated into the practical application which is listed as follows:

- I used my knowledge in chemical engineering to determine the correct dosage of sulfuric acid to be used that is nontoxic and not hazardous to man and the environment.

- I used my knowledge in the selection of materials to choose the correct substances which were suitable for the food product.

- I applied my mathematical knowledge to calculate the size of the new system so that the time taken to complete one cycle was less than that of the previous system.

- I used my knowledge of safety PPE requirements for the chemical system to enhance the safety of the analyst.

- I performed the preventive maintenance of the new system with my knowledge in maintenance engineering.

CE 1.7

The fumes that are generated during the protein digestion process are needed to be controlled. I studied various journals, articles and reports related to the topic of safety of the operator during the processes. The hot surfaces and areas that are hazardous to the operator are considered as condensation zones; where one cannot enter without proper authentication during the processing. The condensation zones are determined to prevent the splashing of the acids on the operator. The release of the acid fumes into the air was very dangerous, so I studied on how to control the fumes that are generated into a less toxic material or gas that would be useful for other applications. I found out that the fumes could be condensed and later be collected in a tank. I studied the pollution control parameters that are necessary to be followed for a food and beverage production company.

CE 1.8

I selected the necessary materials to match the requirements of the new system design. I chose a system that has a shock and thermal proofing body. I inserted fireclay on the plates of the surface of the BUCHI system for the purpose of insulation. I used a Hall Effect sensor for the purpose of a fill level sensor. A safety sensor is chosen that continuously monitors the temperature of the system which stops heating when the temperature reaches a critical limit. The certain dose of sulfuric acid is determined because this acid is a very strong one and the process of protein analysis requires the handling of the acid by the analyst. The glass which is chemical resistant that is thermal and shockproof is required for this system. So, I chose the Borosilicate glass 3.3 that consists of all the required properties. I chose the heating medium for the system to be infrared rays.

CE 1.9

I addressed the issues related to uncontrolled heating in the first part of my project. The existing system was equipped with gas burners to heat the glass tubes used in protein calculation. The heating system was manually controlled which in some cases could result in bursting and chemical spillage if not monitored carefully. The analyst in some cases may face safety risks because of the uncontrolled heating system. I designed the new system which is called the BUCHI system. It was equipped with safety sensors that continuously monitor the temperature of the system. The heating medium here was infrared rays. When the temperature reaches a critical limit, the safety sensor activates and stops the heating. Under this controlled situation, the risk of bursting and chemical spillage is considerably reduced.

CE 1.10

After that, I checked the issue of the hot surface and electric shock in the system. The existing system was an open system which had hot surfaces with the possible risk of burning. There was also a high chance of electric shocks. While working on the system, it is extremely dangerous for an analyst to handle the glass tubes, even with the use of safe handling equipment the chances are not minimized. I designed a new system with exclusive shock absorption and thermal proof body. The plates that are on the surface of the BUCHI system was insulated with the insertion of fireclay. I performed the calculations to decide the size of the new system so that the time taken to complete one cycle was less than that of the previous system. This included the size of the tubes and the critical temperature limit to stop the heating. I calculated the critical temperature limit.

CE 1.11

I designed the pathway for the escape of the acid fumes from the system with an objective to ensure proper condensation and minimum space requirement. Then, I designed the system that had a suction unit which is connected with all the tubes from their mouths. The purpose of the suction unit was to draw out the dangerous vapours so that there is no possibility that these vapours would mix with the laboratory air and the risk is minimized. The sulfuric acid was the major chemical used in the protein digestion process which released acid fumes during the digestion process. However, the current system had a chimney installed on the top of the chamber, but there were chances that the acid fumes do not escape properly and can mix with the laboratory air. This was dangerous for the analyst if these fumes were inhaled. Hence, I proposed the new system considering these factors.

CE 1.12

I considered all of the above design processes and installed the new system. The installation in XXX (Company Name) was very successfully completed. The installation of the BUCHI unit enhanced the safety of the analyst and the efficiency of the protein calculation system in terms of energy saving. I also commissioned the new system under the supervision of the safety manager. After that, I tested the system for its operability. I first run the system on the water to check the status of all the parts connected to the system. The testing was positive after some hit and trials. The suction unit was tested if there were any leaks of the fumes. The tests returned positive, and no fumes were mixed with the air of the laboratory and consequently the atmospheric air.

CE 1.13

After the testing was completed, the full operation of the new system was commenced. The test results were all positive, and so the new system was accepted for use. Then, I performed the periodic maintenance of the new system for optimum productivity. I carried out the daily maintenance which involved turning on and off of the system units. I also carried out the weekly maintenance which involved the lubricating actions of the moving parts. The calendar maintenance was done by me where the sensors could only be operated for 2000-3000 hours.

CE 1.14 Technical difficulties

The glass that was currently being used for the chemical analysis was not resistant to the acids, alkalis and organic substances. It also did not absorb the shocks. This resulted in a serious health hazard for the analyst. After careful discussion with the lab attendant and the process engineer, I decided that the glass should be chemical resistant, thermal and shockproof. Chemically, Borosilicate glass 3.3 contained all the required properties which were later supplied by DURAN.

The fumes that were being released into the air by the sulfuric acid and other organic liquids was causing environmental pollution. It was extremely dangerous to do so even after passing it through the suction tube because it created a lot of health risks to man and the organisms around the site. Hence, I decided to use a condenser for sulfuric acid which was then later collected in a tank.

CE 1.15

I was successfully able to end my term as an executive trainee with the support and guidance from my supervisor. The knowledge that I took from the Safety Manager about the safety requirements for working in such kind of a system helped me to design the line and to use other safety accessories accordingly. The lab attendants helped me in reviewing the existing system and make us aware of the potential risks that they face in their routine activities. I also worked with Mr A who was the process engineer and Mr B who was the Quality Analyst to identify the potential risks in the old and new systems. I used to have weekly meetings every Monday after the morning meeting with the factory manager regarding the progress, pending issues and assigned roles for the week. I also used to meet with my Manager, Mr X every Tuesday morning to discuss the key points. In doing so, I abided by the rules and regulations of the company and maintained my norms and ethics during my term of the project. Since the sulfuric acid fumes are very strong, the predetermined limits of the acid are used for the permissible exposure limit to be as 0.1mg/m3 to 3mg/m3 STEL.

PART-IV SUMMARY

CE 1.16

Working on a chemical analysis project has never been easy because we need to consider a variety of things and situations to perform an activity. A chemical process includes the handling of dangerous chemicals and organic liquids. Working on this project helped me to enhance my theoretical skills to a practical level. I learnt the skill of time management and self-discipline during this project. The old system had safety concerns, but the new system checks all the safety issues, and the environmental effect is also minimum because of the different accessories used to check all the CCPs. The project was well handled, and the project goals and objectives were achieved as planned. However, the time taken for this project was extended by 1 month in order to perform all safety checks. I used my analytical skills to make a fair judgment. The overall project was the responsibility of the Manufacturing, Quality and Engineering team. We worked as a team to achieve our desired goals. My role in the project involved the use of correct materials and equipment to achieve maximum efficiency.